The high rate of development, especially in Indonesia, has supported many private companies in the construction sector to compete. The need for increasingly diverse products has demanded increased flexibility from companies in responding to customer needs.

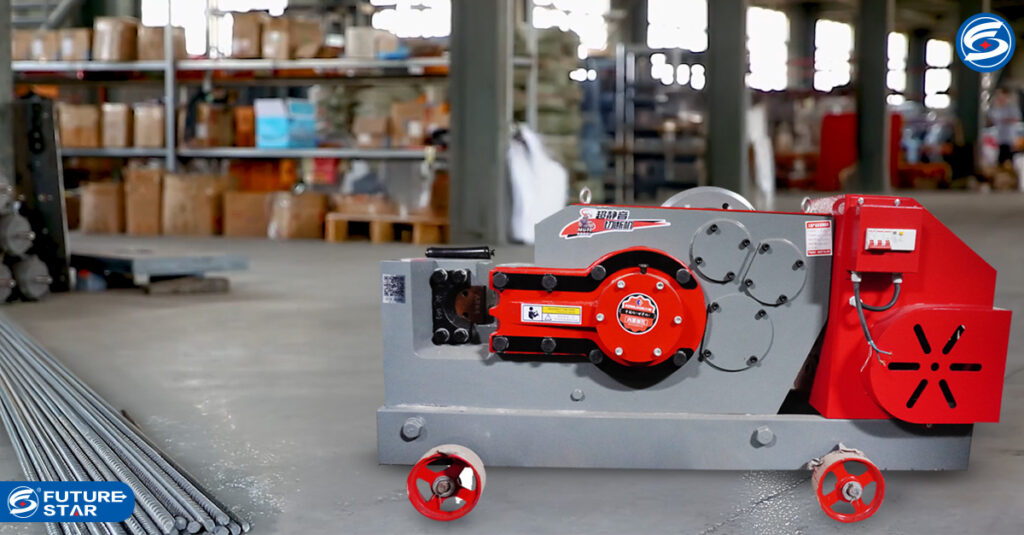

Bar Cutting is one of the machines that has always been a necessity in cutting work. Such as cutting three bars at once with automatic material feeding and clamping using a hydraulic system mechanism.

There are several parts that need to be made to make this project successful. There are basically three plates that hold the beams facing each other, the sliding plates are used to slide over the base plate. There are several types of parts and specific functions which are discussed below:

- 1. Base plate: This is a three-hole plate on which the entire assembly is mounted. The flat back is for mounting the cylinder at the bottom so that the crossbar can be carried unimpeded. It is to limit the free movement of the block (Clamping and Unclamping).

- 2. Sliding plate: These are two horizontal perforated plates that perform the movement of the blocks. One extra square block is welded. At the bottom connected to a cylinder mounted on the base plate to perform the feeding movement in the assembly.

- 3. Fixed plate: The plate is fixed at the front. It serves as a plate as the base only serves as a clamp for the crossbar with the beam at the time the cutting operation is performed.

- 4. Block: This is a rectangular block. With the milling process a small extension is given at the bottom for block guidance.