There are many jobs in the construction manufacturing industry that we encounter in our daily lives. Of course, there are many requirements to be one of the factors to play a role in a job like this.

To be able to do it well, many will become conventional methods. As is the case when working on bending iron or metal which is one of the materials in making the frame of a building.

In the bending process using a machine Bar BendingYou must be experienced. You are expected to know in detail the exact angles of the material to be bent or cut. In the Conventional Method, solid bars are heated and then with the help of a hammer, they are mixed. Without having to go through the process of heating the rod, it is not possible to bend it in the required shape.

However, there are some drawbacks to the above application method, including:

- a. Requires pre-forming on the surface of the metal bar, and,

- b. Notching and cutting had to be completed in separate steps, leading to a complicated preparation process and reduced productivity.

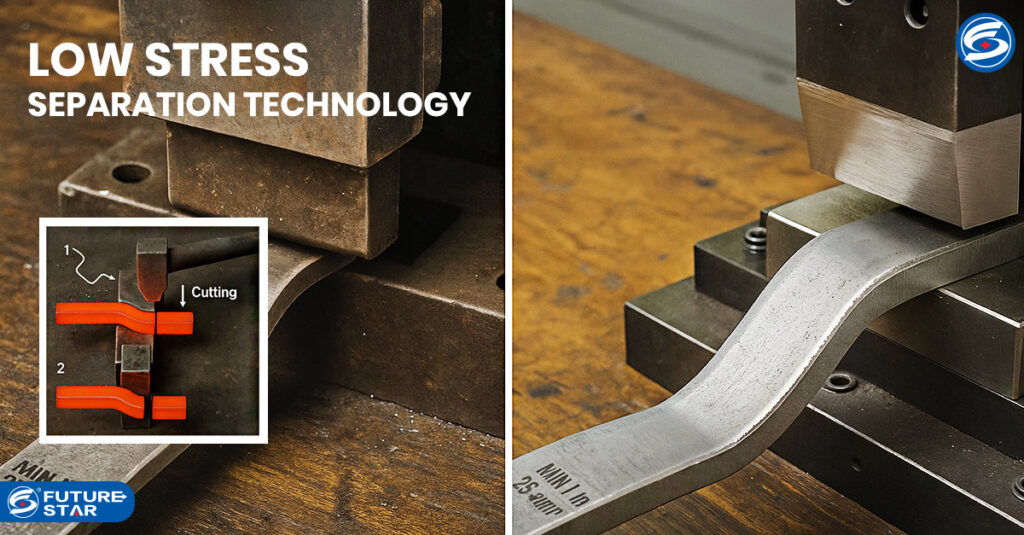

However, this method is considered to be very ineffective, therefore low stress separation machining technology should be a knowledge for engineers and operators in the field. The method combines notching and cutting together to form a synergistic effect on the notching surface through bending.

Loading curve control pre-tension is very important for the quality of cutting parts and cutting force. Many experts have studied the cutting process under pre-tension conditions to explore the influence of pre-tension on the cutting process.

By utilizing the latest technology, especially in construction work which certainly involves heavy equipment in doing so. Bar Cutter, is considered a reliable machine in assisting the process of cutting metal bars. This bar cutter will adjust the cutting speed and pressure to handle various thicknesses and types of metal. By using mechanical strength and high precision to cut metal with optimal results.