In our daily lives, we are never separated from all work activities. One of the jobs that we often encounter is construction work along the way. In the construction industry, pipes are a necessity for every construction unit for the water flow process as a structural component.

Therefore, pipe installation in each type of construction will differ in design and design. Pipe bending activities using pipe roll bending machine has become an attractive manufacturing technology for forming lightweight products. In industrial applications, bent pipes must be accurately formed into 2D or 3D shapes without failure.

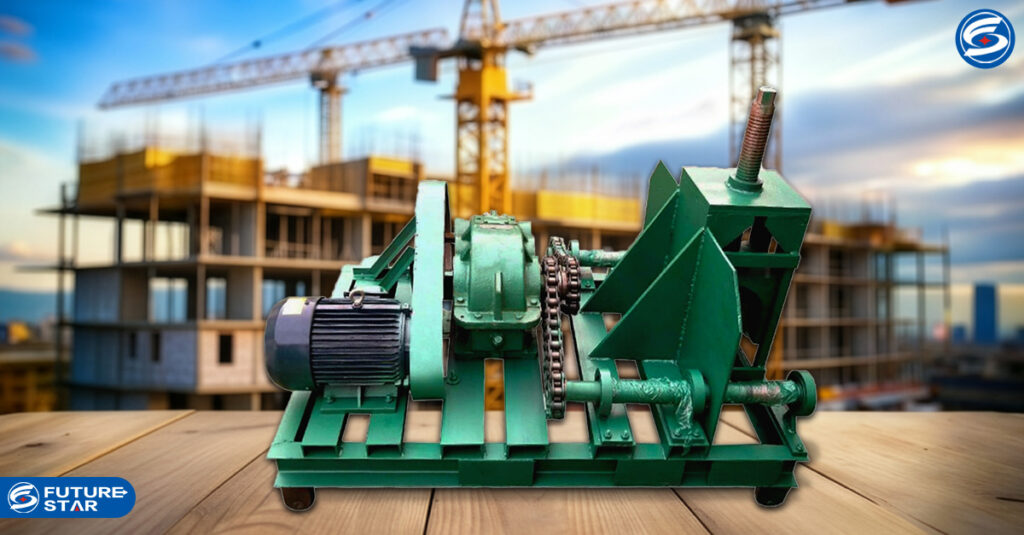

This Pipe Roll Bending Machine in the construction industry is deliberately designed to be able to minimize human labor. In this case, an operator who is still working in the training stage, will still be able to start trying to operate this machine. This Pipe Roll Bending Machine functions as a technical device in bending pipes automatically using pulleys, motors, gears, and frames.

Along with the development of science and technology that is increasingly sophisticated, especially in the infrastructure industry. The development of this machine will continue to be adapted to the needs of construction development to be more accurate.

Pipe Roll Bending Machine can be operated manually or with electric power. In general, pipe bending machines can be operated both with electricity and manually.

The purpose of using these machines in construction work is to improve accuracy at low speeds without sacrificing pipe bending productivity. However, manually operated machines have accuracy which is lower at high speeds.