The successful performance of remote automatic welding of pipe joints depends on precise control of many parameters.

Increasingly sophisticated technological advances in The Age of Digitalization Nowadays, technology is not only impacting the media industry. But with this technological sophistication, it also has an impact on improving the quality of various industries.

The construction industry is one type of manufacturing whose rate of development is very rapid. So that it affects the business chain in increasing the quality and quantity of products of all entrepreneurs.

One of the efforts that must be made in business competition between competitors is to increase productivity. Both in quality and quantity, so as to maintain and fulfill the continuity of the distribution process. However, what we need to pay attention to is how a company can sustain the production process.

In addition, the use of this machine is also influenced by several things, including human resources. Human resources still have an important role in the production process as well as the condition of production facilities such as production machinery and supporting equipment.

In any industry, of course, the company will not be separated from the machine. Because, the machine is one of the most important parts in carrying out various production processes in the company. This is to prevent damage to the machine. Then all production processes will certainly stop, so that it will hamper all other activities, including distribution to customer hands.

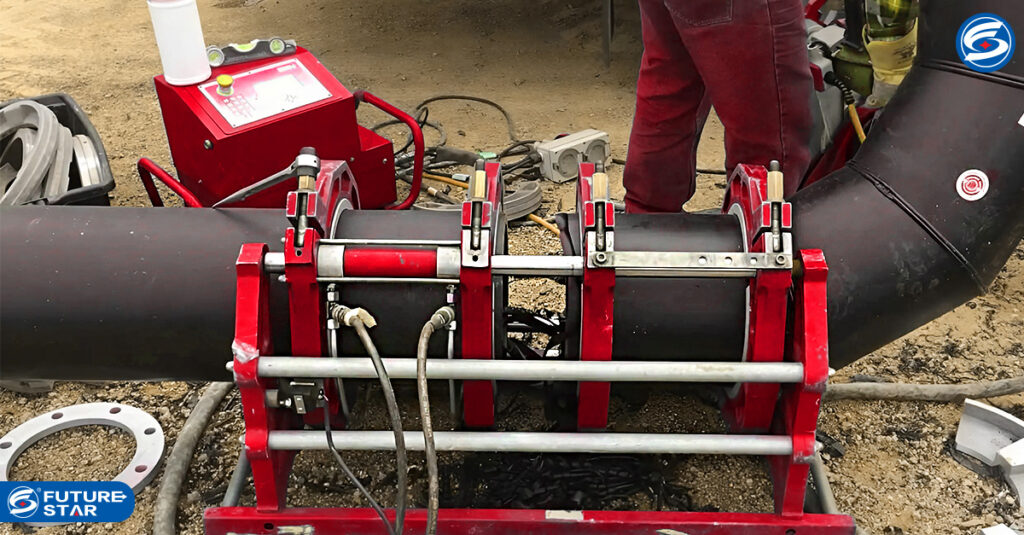

Role pipe jointing machine This is very important in the overall production process. Therefore, the condition of the machine must always be in optimal condition. You as an entrepreneur in a manufacturing industry that deals with production, construction.

This pipe connector machine consists of several vital components, so it can cause these components to be damaged. Therefore, it will result in losses for the company (Zein et al., 2019). A proper maintenance routine will extend the life of the machine. So as to minimize the cost for maintenance of damaged machines (Camerling et al., 2020).

Welding automation of main pipes and other large-diameter long pipes is developing at a rapid pace. As a result, it is possible to improve the quality and output rate while reducing costs and labor intensity.

Automation of rotary joint welding, flange welding, welding tee (pipes) are less developed. This automation process usually applies to large industries. As some of them a wide variety of parts are produced and a small number of similar products. It also serves for multi-pass welding of thick-walled pipes (shipbuilding, aircraft, electrical engineering, etc.).

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.