Along with the development of increasingly sophisticated technology, almost all lines of industry are now experiencing significant changes in the work system. Technology optimization in the digital era is not only experienced by the media industry, but also the heavy machinery and construction equipment manufacturing industry.

Shotcrete is one of the heavy equipment categories that is currently experiencing increasing demand. Despite the increasing importance of shotcrete, a complete guide to the application of shotcrete where shotcrete is one of the equipment as the main support in various conditions is not yet available.

The proposed support based on experimental classification is also based on a database where steel frame structures dominate, and the shotcrete thickness suggested by them needs to be reconsidered. There are several factors that cause tunnel stability analysis under geotechnical conditions to be generally carried out by numerical methods.

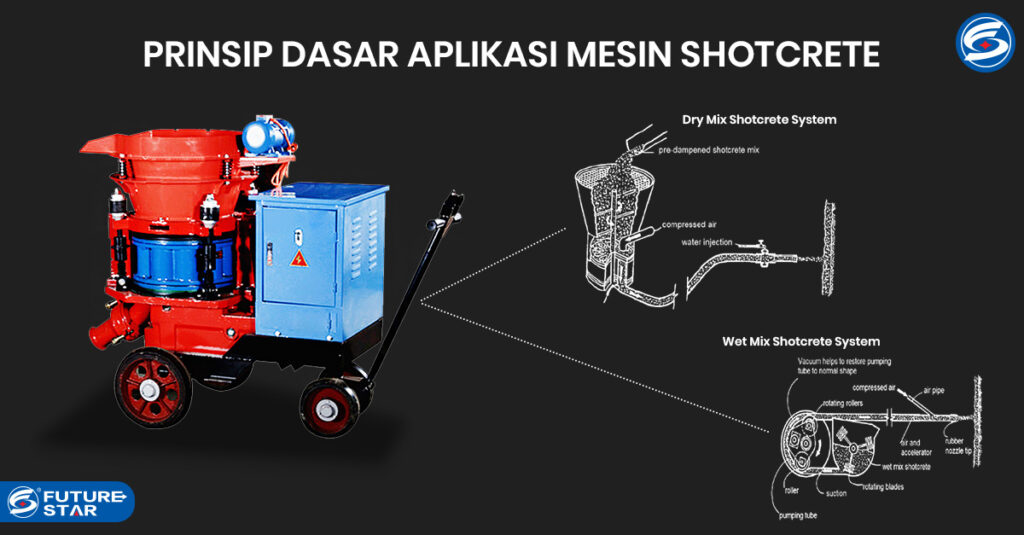

BASIC PRINCIPLES OF SHOTCRETE

Shotcrete serves to place a dry mixture of coarse sand and cement into a pressurized chamber. Which the mixture is usually sprayed into nozzle end, where water is added just before the mixture is sprayed. Therefore, this system is usually referred to as "Dry Process".

In this process the sand and cement mixture is fully mixed with water before being pumped through a fundamentally different machine. The following are 2 types ShotcreteThe following are among them:

- a) Dry Mix Shotcrete : The dry shotcrete mix components, which are conditionally slightly pre-wetted. This aims to reduce dust, is fed into the hopper with continuous disturbance. Compressed air is ducted through a rotating drum or feeder bowl to transport the ingredients in a continuous flow through a hose. Water is added to the mixture at the nozzle end.

- b) Wet Mix Shotcrete : Shotcrete components and water are mixed (usually in a truck-mounted mixer). Before being piped to a positive displacement pump unit, which then hydraulically delivers the mixture to the nozzle. Air is added to spray the material onto the stone surface.