Air Filter or very popular with the name Air Filter is one of the compressor components that functions as a particle remover. Particles can be in the form of solid dust, pollen, mold, and bacteria collected from the air. Some applications that require Air Filters are as follows building ventilation systems and machines such as internal combustion engines, gas compressors, gas turbines, and others.

The purpose of installing an air filter is to filter dust and other foreign particles from the air. Particles would normally enter the system potentially damaging the engine. Air filter is generally made of fiber material that is folded like an accordion.

Manual cleaning of the Air Filter often results in pinholes or other damage to the folded material of the filter.

In order for the performance of the Air Filter to be maximized, you need to use a room with airflow with maximum capacity as well. Here are some things you can do if you use an Air Filter:

- Installation of the air filter on the disk connected to the rotor mounted on the assembly base and secured with clamps.

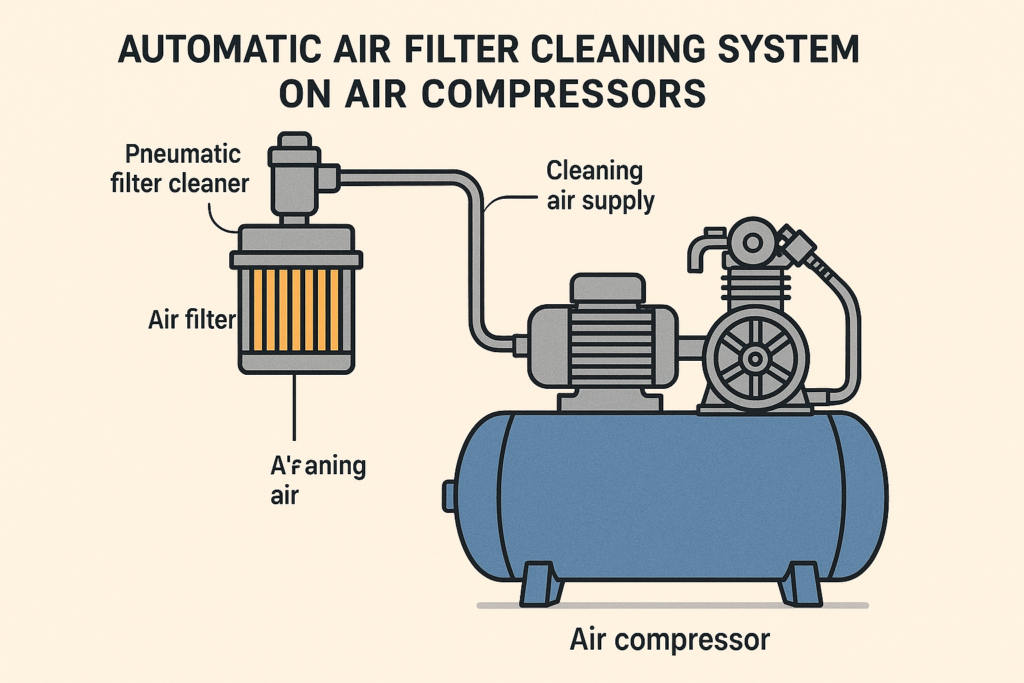

- An aluminum frame mounted on the base of the assembly, consisting of a pneumatic cylinder equipped with a solenoid valve controlled by a microcontroller. Incoming air from the compressor is distributed to the nozzles through pipes.

- Once activated, solenoid valve will activate and control the reciprocating motion of the pneumatic cylinder. And at the same time the motor also starts rotating and rotates the air filter in the same direction. An air pump is used to drive the pneumatic cylinder. An external compressor is connected to the pipeline which supplies compressed air through the pipeline and finally through the nozzle.

- There is rotary motion of the air filter and reciprocating motion of the nozzle. Compressed air enters from an external compressor which serves to remove the maximum number of particles. The particles collect in the air filter from the environment in a short time. Therefore, the air filter will be clean.