In the world of construction, infrastructure and water management, strong and leak-free pipe joints are key to a successful project. The increasingly used HDPE, PP and PVDF pipes require a special welding technique called butt fusion.

These machines are ideal for drinking water distribution projects, gas, sewage treatment, irrigation, and industrial applications. With hydraulic technology and rugged design, they offer high efficiency and precise welding results. This serves to meet international standards such as ISO 21307 for plastic pipe welding.

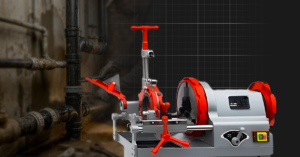

Basic Technology of JLB250-4C and JL-315 Hydraulic

Butt fusion pipe joining machines like JLB250-4C and JL-315 Hydraulic work by melting the ends of pipes and fittings. The trick is to use heating plates, then fuse them together under hydraulic pressure to form a homogeneous joint.

The process of using this machine will produce a bond equivalent to the strength of the original pipe. This makes the pipe more resistant to high pressures of up to 16 bar or more, and minimizes the risk of leakage.

Both machines are equipped with modern features to ensure welding quality:

a. Non-Stick Heating Plate: PTFE coated to prevent material sticking and facilitate cleaning.

b. Milling Tool (Facer): Electric with sharp blades for smooth pipe end surfaces, ensuring optimum joints.

c. Hydraulic/Manual Clamp: 4 adjustable clamps to maintain pipe alignment, preventing distortion during heating.

d. Digital Temperature Control: Minimum deviation of ±7°C, with visual indicator for real-time monitoring.

e. Portability: Lightweight and resilient design, suitable for use in narrow trenches or remote locations.

f. Safety: Equipped with overload protection and ergonomic design to reduce the risk of operator accidents.