Construction design work is difficult to apply to buildings.

The bending process will require professional experience in shaping the building frame design.

To be able to complete construction work in the field, now almost all steps will use machines. This is because construction work is one of the heavy equipment jobs, which almost all steps will require heavy machinery. Therefore, humans as the main resource will not be able to work alone without machines.

In the field of construction design which will later be applied to buildings, of course, it becomes more difficult to apply. Building design cannot be separated from the use of construction materials such as iron and steel for making frames. The work to form this frame design will require a lot of time.

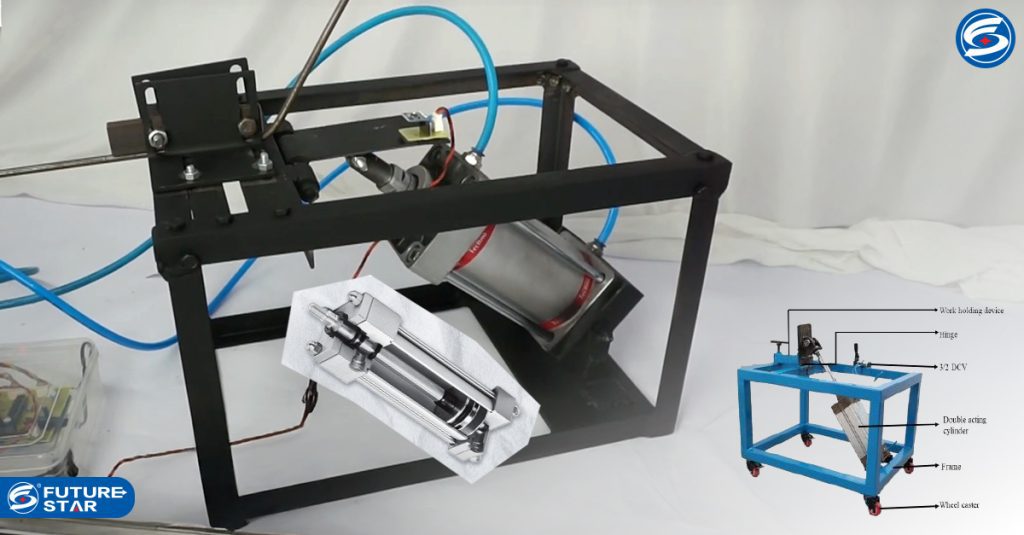

So this project is characterized to perform clamp bending operation using hydraulics and named as hydraulic bar bending machine. The main objective of our project is to implement the hydraulic bar bending machine at the construction site with less cost as compared to the existing bending so as to provide performance efficiency from that we conclude that solar energy can efficiently generate electrical energy to power the engine, and increase the productivity of the clamp.

In every construction project, it will always require a material bending stage as a foundation or building frame. Therefore, the bending process will require a hydraulic steel bar bending machine.

The main objective of this project is to implement a hydraulic bending machine at the construction site. In addition, the use of this bending machine is cheaper than the existing bending machines. So that it provides performance efficiency from which we conclude that solar energy can be efficiently. This bending machine can also generate electrical energy to power the ship, including to increase the productivity of the clamp clamp.

Bending machines will be used in all types of industries including blanking and pressing. There are many different types of bending. The most popular ones are pneumatic bending and hydraulic bending. But pneumatic bending is preferred over hydraulic bending. The biggest advantage of pneumatic bending is the speed of machine performance.

Earlier bending machines were operated by hand, but nowadays in the industry especially in the automotive and other sectors they are operated by machines. But at present, the engineering components of bending operations have undergone changes with the development of technology. This arrangement is made to avoid injury to the operator. The main objective of this project is to have complete knowledge about pneumatic devices.

As for some work projects that apply the use of machines Bar Bending, among them are the following:

- To make a bending machine to bend metal bars up to 10mm.

- Analytical design of MS rod bending machine (Sheet Metal) pneumatics.

- Modeling and simulation of a pneumatic MS (Metal Sheet) rod bending machine.

- Sample preparation of prototype pneumatic MS (Metal Sheet) rod bending machine.

- Test run of the pneumatic MS (Metal Sheet) rod bending machine.

- Comparative study of the yield of a pneumatic MS (Metal Sheet) rod bending machine.