Gas cutting of soft steel profiles, stainless steel, quick steel sheets has tremendous significance in manufacturing work.

The work in the field of construction that we encounter a lot is not only building houses, buildings, hotels, apartments or government service centers. However, work in the construction field will involve a lot of machinery and equipment to complete it. The construction tools that you usually use, can function to do various jobs.

Cutting and punching is an important part of the production process in industry, especially in pipe manufacturing. Using a press, we can cut vertically and perpendicular to the surface of the workpiece, starting from the edge. This is crucial to ensure accuracy and efficiency in the pipe profile cutting of various sizes.

One way to achieve an optimal design is to design a mechanism that is operated quickly. These mechanisms allow us to manufacture various shapes of pipes or tubes with high precision. With this technology, we can meet the specific needs of various industrial applications.

In making ship frames, of course, workers also need construction machinery and equipment. Because the formation of the ship's design will be more or less the same as the house we live in.

The difference is, the ship operates at sea, while the house will continue on the ground (land). In addition, the ship will continue to move according to the direction of the wind, and must be controlled by a Nahkoda according to the destination.

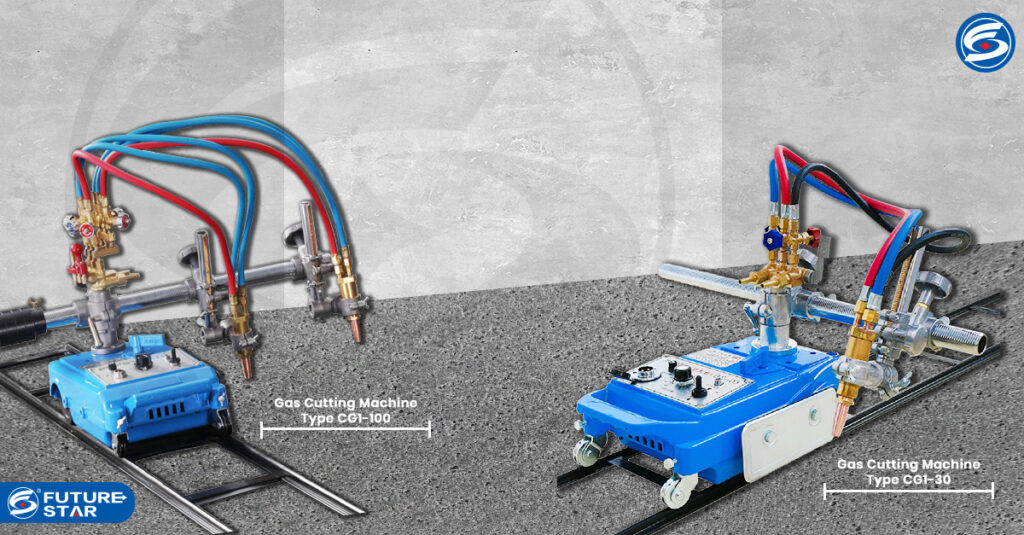

Profile Gas Cutting Machine are in high demand for cutting operations in some industries that have high resistance. In addition, it is also for medium-scale commercial businesses that mostly use manufacturing work techniques.

Gas cutting of soft steel profiles, stainless steel, quick steel sheets has tremendous significance in manufacturing work. Every assembly strategy has a particular prerequisite arrangement that can be fulfilled by utilizing a profile gas cutting machine.