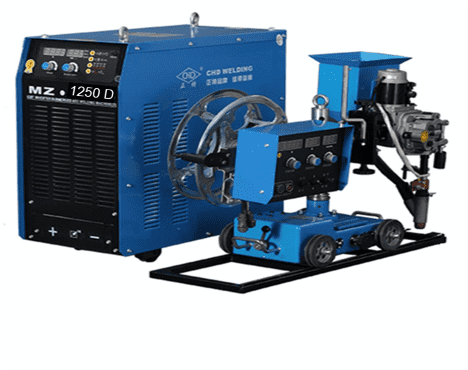

ARC WELDING MACHINE

n

| MODEL | MZ-1250D |

| RATED INPUT VOLTAGE/FREQUENCY | 3~380V 卤 10% 50/60 |

| RATED INPUT POWER (KVA) | 55 |

| RATED INPUT CURRENT (A) | 105 |

| RATED DUTY CYCLE (%) | 100 |

| OPEN LOAD VOLTAGE (V) | 90 |

| OUTPUT CURRENT RANGE (A) | 60-1250 |

| OUTPUT VOLTAGE RANGE (V) | 20-50 |

| POWER FACTOR | 0,87 |

| WIRE DIAMENTER (mm) | 1.6-6 |

| WELDING SPEED RANGE (mm/min) | 100-1500 |

| WIRE FEEEDING SPEED RANGE (mm/min) | 200-2500 |

| WIRE COIL CAPACITY (Kg) | 25 |

| SOLDER FUNNEL CAPACITY (L) | 10 |

| INSULATION GRADE | H |

| POWER SUPPLAY DIMENSIONS WxDxH (mm) | 400x800x885 |

| POWER PACK DIMENSIONS WxDxh (mm) | 465x860x1010 |

| ATTACHMENT SIZE (mm) | 500x1140x880 |

| HOST G.W / OVERALL POWER SOURCE G.W (Kg) | 124/224 |

| WELDING THICKNESS (mm) | 25-May |

PRODUCT ADVANTAGES

n

| Soft switching inverter technology, energy-saving design, no arc in 30 minutes interval, automatic cut off circuit power |

| Light weight, small size, easy to move |

| High load duration, can work continuously throughout the day |

| High energy, slow cable feeding Arc start, success rate 100% |

| No contact control, high reliability |

| All have constant current characteristics, welding wire diameter 3.0-6.0mm |

| Pulse width adjusts wire feeding and trolley driving speed, less affected by network fluctuations |

| electricity and temperature changes |

| The wire feeding device is two-wheel drive and elastic wire pressing to ensure wire feeding |

| that is stable and reliable. |

| Variable speed and constant speed two-wire feeding method |

| Various trolleys are optional to meet the needs of various welding positions. Function: submerged arc welding, |

| carbon arc gas |

| Innovative and manual arc welding applications: shipbuilding, boilers, bridges, surfacing, steel structures, wind towers, etc. |